Introducing a new line of kayaks and sursfkis designed in Scandinavia for the world market

The best of both worlds

We believe there is more to be gained by combining the best qualities from sea kayaks and surfskis, than has yet been utilized...

read more →

Rethinking the basics...

Rethinking a lot of small details normally taken for granted, for low weight, comfort and elegance...

read more →

Comfort, safety and looks

These are perhaps the most important qualities in any watercraft. We took it a little further...

read more →

Kayaks and surfskis

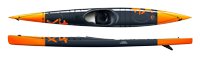

AXIS X4

507x55 cm

AXIS X4 sport

507x51 cm

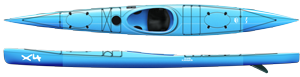

AXIS X3

494x55 cm

AXIS X3 sport

494x51 cm

AXIS X2

460x53 cm

AXIS S4

507x55 cm

AXIS S4 sport and S2 Sport

507x51 cm (coming)

AXIS S2

460x53 cm

AXIS X4 PE

507x55 cm

A new light, efficient and versatile greenland paddle

About Axis Kayaks and surfskis

Axis Kayaks

Axis Kayaks was formed in 2012 by Sveinung Kristiansen, primarily to explore a market segment that he felt was ignored by most other companies. Working together with designer Björn Thomasson, the specifications were established and the design process started for a new line of sea kayaks and surfskis with cutting edge design and construction based on a wealth of paddling experience and knowledge in sea kayak design and kayak retailing.

In close cooperation with our manufacturing company, we have pushed the boundaries of production techniques and advanced materials to create light, strong and efficient watercraft at the very forefront of the kayaking scene.

Construction

All Axis sea kayaks and surfski use the best construction technology that is currently available, including woven and directional glass fiber, carbon/kevlar combinations and woven carbon fiber. Highest quality epoxy resin is used in every laminate. The composite laminates are either molded by hand or by vacuum-infusion, depending on the construction type. An epoxy compatible polyester gelcoat is used which facilitates easy repair should the kayak be damaged in use.

Construction options

PRO: vacuum infusion fiberglas/soric honeycomb/epoxy

PRO ULTRA: 100% carbon/honeycomb/epoxy

PE: Rotomolded Polyethylene

Take care of your kayak

If possible, wash the kayak in fresh water after salt-water use. Salt absorbs moisture and may lead to gelcoat problems due to osmosis over time. If you store your kayak outside, keep it up side down. Protect it from direct sunlight to preserve the deck ropes and elastics – and also the gelcoat, that after years in sunlight may fade and become dull. Remove the hatches for long time storage to ventilate the compartments. If covered, make sure the tarp does not touch the hull. Position cradles or straps at the bulkhead positions to avoid distortion of the hull.

Gelcoat scratches and chips are unavoidable, but normally not critical. Scratches exposing the laminate must be repaired, since moisture in the cloth may cause delamination when the temperatures drop below freezing. Dry out and apply new gelcoat as needed.

Check deck lines and elastics for wear and tear, and replace them if needed.